Contents

How many bags of cement required for slab construction

Cement is the fine pozzolanic material used in the building construction. The main aim of the cement materials is to bind the aggregates namely fine aggregates and coarse aggregates in the specified grade of concrete like M20, M25, and M30 etc. The major general raw materials used in the cement manufacturing are limestone, clay and marl. In this article you can able to learn number of cement bags required for slab construction.

In the market cement material are available with 50kgs bags with different types like ordinary Portland cement, pozzolanic Portland cement, rapid hardening cement, extra rapid hardening cement, low heat cement etc. But in the building constructions now a day’s most of the engineers are using OPC (ordinary Portland cement) and PPC (pozzolanic Portland cement) types because of their various advantages over the other types.

The bureau of Indian standard (BIS) classified the grades of OPC cement in to three types namely 53grade, 43grade and 33grade. Depending upon the various requirements for the project the type of OPC is selected initially before the construction work.

How many bags of cement required for different plan configurations which are described below.

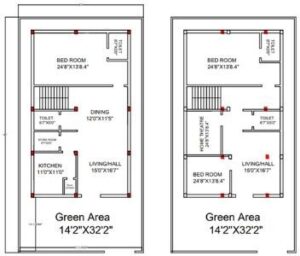

Model 1: G+1 duplex structure

The above typical floor plan shows the G+1 duplex house building which is having road way in the east facing direction. In the ground floor section it is consisting of kitchen, hall, wash area, dining and one bed room. In the similar way the first floor section is consisting of two bed rooms, Hall, living, home theater and wash area. For this model it is consisting of the length of the slab in X direction is approximately 28’0” and again in the same process the Y direction is contains 58’0”. By converting the values in to meters we will get 8.5344 meters in length direction and 17.6784 meters in width direction.

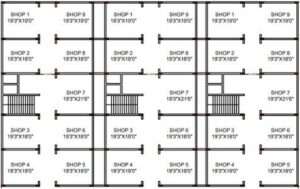

Model 2: G+3 commercial structure

The above floor plan shows the commercial structure which is having 27 shops in each floor and total shops is having 81 total numbers. The total horizontal direction (X) distance is approximately having the value of 161’0” and in vertical direction (Y) distance is approximately 100’0” value. By converting the values into meters it will get approximately 49 meters in length direction and 30.5 meters in the vertical direction.

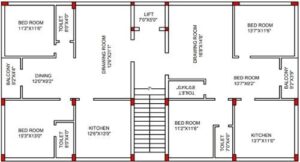

Model 3: G+4 small apartment structure

The above typical floor plan comes under the small G+4 apartment building which is consisting of 8 flats with 20 numbers of the columns sections having different cross section dimensions. The above plan consisting of slab dimensions in X direction is approximately 70’0” and in Y direction is approximately 30’0”.

By converting the values of length and width in to meters we will get total length of the slab is 21.336m and width is 9.144m dimensions.

Estimation of cement required for building construction

Here in this example let us consider M25 grade concrete mix which is having mix ratio of 1:1:2 with w/c of 0.45.

Model 1: Slab having 8.5344 meters length and 17.6784 meters

By taking slab thickness of G+1 building is 125mm

Volume of the slab = length of slab X width of slab X thickness of slab

= 8.5344X17.6784X0.125

= 18.86 m3.

Now as per the M25 grade concrete mix

Density = (Mass of slab /Volume of slab)

By taking density of Reinforced concrete is 25Kn/m3 value

Mass of slab = 2500X18.86 = 47150 kgs

Now by equating the mass of slab with mix proportions

Cement + Fine aggregate + Coarse aggregates + Water = 47150 kgs

1a+1a+2a+0.45a = 47150

4.5 a = 47150

a = weight of cement = 47150/4.5 =10478 kgs

By diving total weight with 50kgs we can obtain number of bags of cement.

So number of cement bags = 10478/50 = 209.55

So for making G+1 building slab having 8.5344 meters length and 17.6784 meters it is required 210 bags of cement in each floor. Totally it is required 420 bags of cement for 2 slabs.

Model 2: G+3 commercial structure Slab having 49 meters length and 30.5 meters

By taking slab thickness of G+3 building is 150mm

Volume of the slab = length of slab X width of slab X thickness of slab

= 49X30.5X0.150

= 224.18 m3.

Now as per the M25 grade concrete mix

Density = (Mass of slab /Volume of slab)

By taking density of Reinforced concrete is 25Kn/m3 value

Mass of slab = 2500X224.18 = 560450 kgs

Now by equating the mass of slab with mix proportions

Cement + Fine aggregate + Coarse aggregates + Water = 47150 kgs

1a+1a+2a+0.45a = 560450

4.5 a = 560450

a = weight of cement = 560450/4.5 =124545 kgs

by diving total weight with 50kgs we can obtain number of bags of cement.

So number of cement bags = 124545/50 = 2491 number of bags

So for making G+ 3 commercial structures Slab having 49 meters length and 30.5 meters it is required 2491 bags of cement in each floor. Totally it is required 9964 bags of cement for 4 slabs.

Model 3: G+4 small apartment structure slab having 21.336 meters length and width is 9.144 meters width

By taking slab thickness of G+4 building is 150mm

Volume of the slab = length of slab X width of slab X thickness of slab

= 21.336X9.144X0.150

= 29.27 m3.

Now as per the M25 grade concrete mix

Density = (Mass of slab /Volume of slab)

By taking density of Reinforced concrete is 25Kn/m3 value

Mass of slab = 2500X29.27 = 73165 kgs

Now by equating the mass of slab with mix proportions

Cement + Fine aggregate + Coarse aggregates + Water = 73165 kgs

1a+1a+2a+0.45a = 73165

4.5 a = 73165

a = weight of cement = 73165/4.5 =16259 kgs

By diving total weight with 50kgs we can obtain number of bags of cement.

So number of cement bags = 16259 /50 = 325.17 number of bags

So for making G+4 small apartment structures Slab having 21.336 meters length and width is 9.144 meters width it is required 326 bags of cement in each floor. Totally it is required 1630 bags of cement for 5 slabs.

See the complete details about this topic in my YouTube Channel Civil engineering by shravan

The complete details of number of cement bags required for the slab are shows in the below table.

| S. No | Building type | Length | Width | Number of cement bags |

| 1 | G+1 building | 8.5344 meters | 17.6784 meters | 420 |

| 2 | G+3 commercial structure | 49 meters | 30.5 meters | 9964 |

| 3 | G+4 small apartment structure | 21.336 meters | 9.144 meters | 1630 |

Follow our previous Floors here

Basic concepts of bar bending scheduling [BBS] in building construction

What are bracings different types of bracings used in the building construction

Design requirements of RCC slab as per standards

Basic rules in foundation design as per standards

Which cement is best OPC or PPC in building construction?

Conclusions of number of cement bags required for slab construction

The above explained concepts are related to the number of cement bags calculation for M25 grade concrete mix with various areas of the slabs for 8.5344 meters X 17.6784 meters slab it is required approximately 420 bags, for 49 meters X 30.5 meters slab it is required approximately 9964 bags and finally for the 21.336 meters X 9.144 meters slab area it is required approximately 1630 bags of cement.

For more information related to the civil engineering See the complete concepts in my YouTube Channel Civil engineering by shavan.

Feel free to reach us through contact us page.

Thank You,

Your Shravan,

Have a good day.