Contents

Basic concepts of bar bending scheduling [BBS] used in building construction

The basic concepts of bar bending scheduling include the standards, basic formulas and basic concepts used before the steel bars bending in the construction site. The main concept in the BBS includes the specifications like cutting length, concrete cover, spacing, grade of steel material. Before making the bending of the bars these standards gives an important knowledge for every site engineer, civil engineer or site supervisor in the construction site.

The main concepts of the bar bending scheduling are classified in to the following groups in the building construction

- Diameter of the reinforcement bar

- Standard length of the steel bars

- Weight of the reinforcement bar per meter length

- Cutting length of bar

- Over lapping length

- Concrete cover

- Spacing

- Number of steel bars

- Grade of reinforcement bars

Diameter of the reinforcement bar

The diameter of the reinforcement bar is depending upon the construction type whether it is low rise building, medium rise building or high rise building construction. The diameter of the reinforcement bars in building construction are basically used which are having 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 28mm, 32mm, 36mm and 40mm. in case of single storey building we can utilize 6mm diameter bars under certain conditions in the same process in case of high rise models we use 36mm or 40mm diameter bars in building construction.

Standard length of the steel bars

The average standard length of the any steel reinforced bar is 12m which is approximately 40 feet in the length.

Weight of the reinforcement bar per meter length

The single reinforcement bar of any diameter with 40 feet length value of the weight is calculated by using expression which is D2/162.

For example let us consider the reinforced bar which is having 12mm diameter. The weight of the reinforcement bar per meter length is 122/162 which is approximately equal to 0.888kgs.

In the same process example let us consider the reinforced bar which is having 10mm diameter. The weight of the reinforcement bar per meter length is 102/162 which is approximately equal to 0.617kgs.

Cutting length of bar

The cutting length of the reinforcement bar is the total length of the steel bar used in structural elements like beams, columns, slabs or foundation. The cutting length of reinforcement bar model is classified into two types one is related to the hook type model and second one is bend type model.

Hook type cutting length is given by the two expressions given below in that first step is to determine the length of the hook and next step is to determine the length of main bar.

Length of hook = 9D

Length of main bar = L+9D+9D

The cutting length for the bend type is also given by two formulae which is provided below in that the first step is to determine the bend and next step is to determine the length of main bar.

Length of bend = 10d to 16d

Length of main bar = L+12d+12d

Overlapping length

Overlapping length of the reinforcement bar is generally used if the length or height of the structural member is increases to 40 feet. The overlapping length for the different sections are given in the below sections.

- Neck to column footing overlapping length = 40d to 50d

- Column to column or beam to beam overlapping = 50d

- Development of the dowel bar = 16d.

Example if we take 10mm diameter reinforcement bars

Neck to column footing overlapping length = 50d = 50X10 =500mm

Column to column or beam to beam overlapping = 50X10 = 500mm

Development of the dowel bar = 16X10 =160mm.

Concrete cover

The cover in the concrete structure is generally defined as the distance between the edge or corner of the structural member to the reinforcement bar which is exist in that particular member like beam, column, slab or foundation etc. Frequently we will use 25mm or 30mm minimum concrete cover values for the beams and columns section.

The below table shows the minimum concrete cover used in the various components of the building structure.

|

S. No |

Building component |

Concrete cover |

|

1 |

Footing |

50mm |

|

2 |

Column |

40mm |

|

3 |

Beam |

25mm |

|

4 |

Slab |

20mm |

|

5 |

Stair case |

15mm |

|

6 |

Chajja |

15mm |

|

7 |

Pile |

60mm |

| 8 |

Pile cap |

60mm |

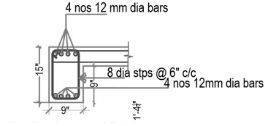

Spacing of the reinforcement bars

Spacing is the center to center distance between the reinforcement bars for the beam, column, slabs or footings. For the basic structures we will use 100mm, 110mm, 150mm or 180mm spacing in the building construction.

Number of the bars

The number of the bars in the structural components are determined by using two expressions.

Number of main bars = (opposite length/Spacing) +1

Number of stirrups = (actual length of the column or beam/Spacing) +1

Cutting length for stirrups

The cutting length of the stirrups is given by using the formulae which is given below

Cutting length of stirrups = perimeter of shape of member + total hook length- total bend length

Type of reinforcement bars

The reinforcement bar type is also called as the grade of the steel bars used in building construction. Now a day’s in the structural design the steel grade is used with Fe415, Fe500, Fe600 etc

The complete concepts of bar bending scheduling [BBS] used in building construction is explained in my YouTube channel find the concepts with below specified video.

Follow our previous posts here

What are bracings? Different types of bracings used in building construction?

Design requirements of RCC slab as per the standards?

Basic rules in foundation design as per the standards?

Which cement is best OPC or PPC in building construction? And why?

What is wind terrain category? Different type of wind terrains used in building design?

Conclusions of basic concepts in bar bending scheduling

Now the above explained concepts are related to the basic principles are standards used in bar bending scheduling which are related to the diameter of the reinforcement bar, standard length of the steel bars, weight of the reinforcement bar per meter length, cutting length of bar, over lapping length, concrete cover, spacing, number of steel bars and grade of reinforcement bars.

For more information related to the civil engineering concepts follow my YouTube channel Civil Engineering by Shravan.

For any quarries about this article feel free to reach me through contact us page.

Thank You.

Have a nice Day.