Contents

How to determine the flexural strength of the concrete ? Beams bending strength of concrete ?

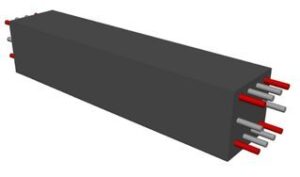

Flexural strength is the one of the important property of the concrete strength it is generally determined for the beam specimens. The casting of the beams are made with the shape of prism. Generally the standard size of the beams related to the 150mmX150mmX700mm otherwise the size of 100mX100mmX500mm are used in the concrete testing laboratory for the determining the flexural strength of concrete. The value of the flexural strength of the concrete is expressed in the units of N/mm2 or MPa. The flexural strength of the concrete determined as per the IS 516-1959 standards.

The following step by step process is used for the determining the flexural strength of the concrete specimen.

Grade of the concrete and proportions of the material

Grade of the concrete is the considered initially before casting of the test specimens. Examples of M5, M10, M15, M20 etc are used as the grades of the concrete. For example let us take the grade of the concrete of M15 which is having mix ratio of1:2:4 and consider w/c is 0.4.

Batching of the test materials

The batching is the process of determining the quantity of the test materials. The batching of the materials are two types which are related to the weight batching and volume batching. In this case of M15 grade concrete mix take weight batching.

After considering the mix proportions of the materials used in the concrete making, the quantities of materials are determined related to the cement, fine aggregates, coarse aggregates and water according to the consideration.

Mixing of the concrete

Now the next stage is to mix the materials to make the concrete. Initially the coarse aggregates and fine aggregates are mixed then add the cement material to the mixture of aggregates (combination of fine aggregates and coarse aggregates). Now mix the total materials properly until it gets the uniformity. Then add the suitable amount of the water for the mixture again mix the material mixture till the homogeneity obtained.

Casting of the test specimen

Now the next stage is the casting of the specimens the prisms of 150mmX150mmX700mm or 150mmX150mmX500mm mould are considered and apply the lubricant for the sides of the mould. Now fill the one third of the mould with concrete material which is prepared in the above step and apply the compaction of the concrete with the help of the tampering rod as 25 blows.

Now again fill the mould with another one third and again apply the tampering with again 25 blows. And fill the remaining material with last one third layer and compact with tampering rod again. Now after compaction process is done remove the excess of material of concrete of the mould and make the smooth surface with the help of the trowel.

After casting process is done allow the specimens for the hardening process till 24 hours from the time of casting process.

Curing f the test specimen

After done with 24 hours hardening process de mould the concrete beams from the mould. And transfer the specimen to the water curing tank allow them for the curing process for the specified curing period for 7days, 14days, 28days etc.

Flexural strength of concrete test process

Now the next stage is to check the flexural strength of the concrete for this remove the beams from the curing tank and remove the moisture content from the top of the beam specimen. Allow the specimen to get hard at room temperature.

Now mark the 5cm on to the right of the specimen and left of the specimen. Place the test block above the two points of the specimen with the distance between the each support is considered as 20cm. Now apply the load on the test specimen until it reached to the maximum limit. Due to the presents of the load the cracks will be observed in the beam. The load in the gauge is noted which is P (the maximum load required to break the specimen).

The flexural strength value of the concrete determined depending upon the crack position

Case A: If the crack is greater than or equal to the 20cm. the following equation is used.

Flexural strength = (PL)/bd2

Where P = Applied load on the specimen,

L= Length of the specimen,

b= width of the specimen,

d= depth of the specimen,

Case B: If the crack is less than the 20cm. the following equation is used.

Flexural strength = (3Pa)/bd2

Where P = Applied load on the specimen,

a= Length of the crack,

b= width of the specimen,

d= depth of the specimen,

Case C: If the crack is less than the 17cm.

If you observe this case in the testing process repeat the test again.

Follow our previous five posts

What are the different ingredients used in the bricks making?

What is the grade of the concrete ? mix ratio and water cement ratio of concrete?

What are the top five buildings in the world according to the height ?

Conclusions how to determine the flexural strength of the concrete as per the IS code standards ?

Well now the above explained concepts are related to the determination of flexural strength of the concrete as per the standard. For the flexural strength of the concrete we will use the dimensions of the specimens related to the 150mmX150mmX700mm or 100mmX100Mx500mm are used. The IS 516-1959 code us frequently used. The strength (flexural) formulae is depending upon the cracking length and location. If the crack is greater than or equal to the 20cm use (PL)/bd2, If the crack is less than the 20cm use (3Pa)/bd2 and in the final case if the crack is less than the 17cm repeat the test.

For more information related to the civil engineering concepts and updates follow my YouTube channel civil engineering by shravan.

Note: The above concepts and information only helps for the civil engineering students to get brief idea regarding the topic. Do not consider it for the real time applications.

Thanks for reading this article,

Your shravan

Have a nice day.