Contents

Difference between the working stress method (WSM) and limit state method (LSM) which method is best in the designing of the building

The design of structural elements means finding the dimensions of the members (beams, columns, slabs, footings etc) and reinforcement details of the structural components. Mainly the designing of the members will be done by following two methods namely

- Working stress method (WSM)

- Limit state method (LSM)

Working stress (WSM) method

This method was developed in 1900 year. It is old method and it is a traditional method. This method is used for the RCC structures design, steel structures design and timber design also. Working stress method is first theoretical method accepted by the all-national codes and it is elasticity method. The design of the members is considered as per the modular ratio because of that reason it is also called as modular ratio method. The design of the structural members as per the working stress method is based on the stress values.

The following are the assumptions used in the designing of the members as per the working stress method (WSM)

- Plane sections are remains in plane cross section before and after bending of the members.

- Concrete tensile strength is not considered only compressive strength values are considered.

- Steel and concrete members acts together linear elastically because the stress is directly proportional to neutral axis distance.

- The value of modular ratio is taken as 280/3cbc.

Factor of safely used in the working stress method

Factor of safety is the ratio of the ultimate stress to working stress (or) yield stress to working stress. For the brittle materials, we will consider the ultimate stress and for the ductile materials, we use the yield stress.

Factor of safety (FOS) = ultimate stress/working stress (or)

Factor of safety (FOS) = yield stress/working stress

FOS for concrete =3, FOS for steel =1.78

Disadvantages in working stress method

Because of the old methodology of designing the members, it has several disadvantages in the structural design they are

- This method (working stress method) gives original strength of the materials not gives true factor of safety at the time of failure.

- The steel obtained for the working stress method is high when we compared with limit state method, which leads in the un economical design of the structure.

- There is no proper modulus of elasticity (Ec) because of the creep and nonlinear stress and strain curve of the concrete members.

Limit state (LSM) method

It is an ideal method in the deigning the structural members by considering ultimate strength values. Moreover, this method used in serviceability and durability requirements. This method has acceptable requirements before failure occurs.

The following are the assumptions considered in the limit state method (LSM) design

- Plane sections are remains in plain cross section before and after bending which is described by the Bernoullis.

- The maximum value of the stain under the extreme fiber under bending is considered as 0.0035.

- Before the failure of the member the strain in the tension steel shall not be less than the 0.002+0.87fy/Es

- The shape of the stress strain curve is rectangle and parabola. Up to compression zone we will considered as rectangular shape and then it will follow parabola shape.

- The design strength values of concrete is taken as 0.446fckand for the steel is taken as 0.87fy.

FOS for concrete =1.5, FOS for steel =1.15

Disadvantages of the limit state method

There is one disadvantage which is observed in limit state method which is it cannot provide sufficient strength and service during the worst load combination.

Difference between the working stress and limit state methods

| S. No |

Working stress method |

Limit state method |

|

1. |

Old method and it is a traditional method | It is updated method by considering disadvantages of WSM |

|

2. |

This method is stress governing method | This method is stain governing method |

|

3. |

Permissible stress = Yield stress/FOS | Permissible stress = Ultimate stress/FOS |

|

4. |

The factor of safety for the load cases is not considered in this method | The factor of safety for the load cases is considered in this method |

|

5. |

This method is not economical design | This method is economical when we compared with WSM |

|

6. |

This method is based on elastic theory of materials | This method is based on the relation between the stress-strain curve |

Follow our previous posts here

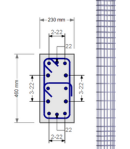

- What is the column size for 2 storey and 3 storey building considered in civil engineering

- How to calculate the volume and cost of concrete required for beams, columns and slabs

- Define cost estimation, methods, and types of cost estimation used in the building construction

- Testing of the bricks and specifications as per the IS code standards

- Types of rolled steel sections used in the civil engineering. Steel members ISLB, ISMB, ISLC, ISNT.

Conclusions of difference between the working stress method (WSM) and limit state method (LSM)

Well now, the above-explained concepts are related to the some important difference between the working stress method and limit state method. The working stress method is old method and it is stress governing method and it is having some limitations and disadvantages because of that reason now a days most of the people are using limit state method in the designing of the structural components namely beams, columns, slabs and foundations etc.

The limit state method is considered as strain governing method. The factor of safety is considered as 1.5 for the concrete and 1.15 for the steel in the limit state method. The factor of safety is taken as the 3 for the concrete and 1.78 for the steel. The working stress method is not economical because of the high dimensions of the members and reinforcement. The limit state method is economical because of the suitable reinforcement and cross section of the members.

For more interesting updates on civil engineering, concepts and topics please follow in my YouTube channel civil engineering by Shravan.

Thank you reading this article,

Your Shravan,

Have a nice day.